Insulation values are a foremost consideration in the search for products that help a building achieve energy compliance and good comfort levels. These are largely dictated by a product’s composition. For example, foil-faced PIR insulation’s 0.022 lambda value, which makes it ideal for fabric-first design, significantly depends on its low emissivity foil facing and closed cell foam structure. But since the development of Eurowall® +, form has become an important function in PIR selection.

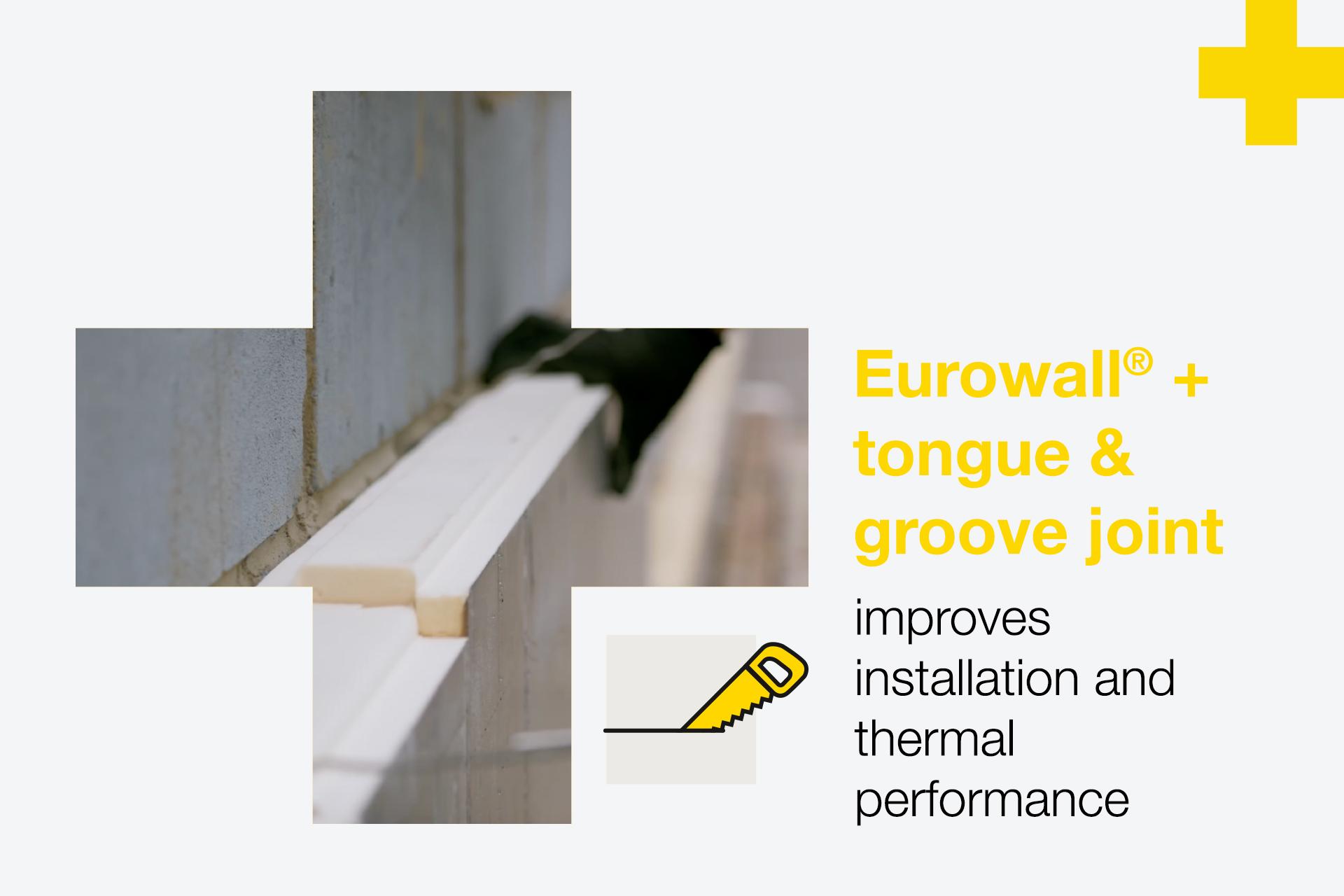

Unlike many other rigid full-fill PIR insulation boards, Eurowall® + features a tongue and groove joint on its four sides. The precision-cut element ensures the boards lock together for a tight-locking fit. This reduces thermal bridging and is integral in enabling a 90mm Eurowall® + board to achieve a U-value of 0.18 W/m²K within a 100mm wall cavity. The 10mm gap generated by the board’s good thermal properties makes it a product that benefits the installer, as well as the end user. For bricklayers, this means traditional techniques can be followed, resulting in a time and cost-effective installation process that is simpler and less labour-intensive. For homeowners, the superior thermal performance offered by the Eurowall® + board is a pathway to significant energy savings and year-round internal comfort.

The time-saving aspect of the Eurowall® + installation process is particularly relevant to the current construction climate. Building projects being subject to ever-stricter timeframes increases the need to develop methods that speed up construction without compromising performance quality. A 2022 survey of construction professionals carried out by utility plans provider, Cornerstone Projects, revealed 91% of respondents had been involved in a recent project that had experienced delays.

A Board that Makes for Good Insulation Time and Space

Time is money in the construction industry, and delays can have a significant knock-on effect in terms of costs and business reputation. Poor weather, material shortages and a lack of funds…there are many reasons for building completion dates being deferred. Overcoming complexities, whether they be related to product design or a particular building process can also cause schedules to overrun. It’s where Eurowall® + comes into its own as an insulation board. Its tongue and groove feature eliminates the need for taping at joints. Additionally, the board’s two distinctive facers remove the guesswork for installers when it comes to fitting them the correct way around.

Technical know-how and ingenuity were integral to the development of Eurowall® +. Such enterprise will be crucial to further evolving products that reduce the built environment’s CO2 impact. This will be driven in part by energy compliance levels, which are sure to further strengthen in the years to come. Interim Part L legislation, which requires new homes to produce 31% less CO2 than previous legislation, is a stepping stone to the Future Home Standard’s introduction in 2025. This will require new homes to produce 75-80% less CO2 than homes built under current regulations. However, with concerns over the UK’s net zero ambition faltering ahead of the 2050 target date, stricter standards are likely to be required in order to limit the country’s carbon footprint.

Available in 90mm, 115mm and 140mm thicknesses, Eurowall® + offers up to 65% better thermal performance than other insulation products of the same thickness. This not only gives it a strong position in the marketplace, it makes it a genuine option for housebuilders looking to futureproof their building’s energy performance against further regulation rises.

Thanks to its tongue and groove profile, Eurowall® + could be the shape of things to come for PIR boards that are a gift for housebuilders and end users alike.

Eurowall® + can benefit your next building project

Click the button below to find out more!