Raw materials: our No.1 focus

🡄 Go to sustainability overview

The core of every PIR insulation board is raw materials, most of which are sourced from fossil fuels. Hence, over 70% of the total Recticel Insulation carbon footprint is determined by the raw materials we use. To cut our carbon emissions and reach for a circular product, they are our first and primary focus.

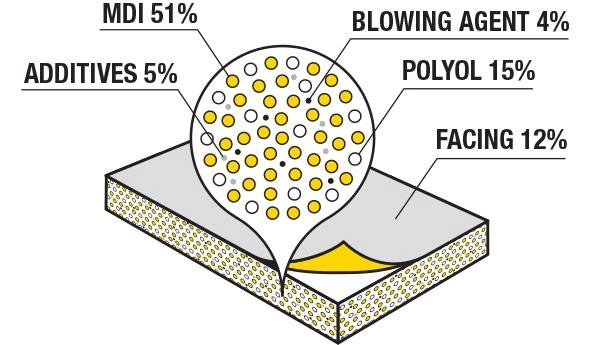

The different layers of PIR

So what components are PIR insulation boards made of? What percentage does that component contribute to CO2 emissons. And how can we replace them, upholding the same quality standards? Let’s take a look at the different components of a Recticel board. The percentages below show the share of this raw material in the total carbon footprint (cradle-to-gate A1-A3):

Example: multi foil faced board:

MDI (51%)

Polyol (15%)

Blowing agent (4%)

Additives(5%)

Facing (12%)

Blowing agent and additives are needed to produce our insulation boards. Our insulation boards are produced without the addition of harmful CFCs/HFCs.

Next to our thermal insulation range, we also have an acoustic insulation range. Our acoustic insulation is almost completely circular, using old matresses as a raw material. The share of MDI’s total carbon footprint is 51% (cradle-to-gate A1-A3).

Projects

We have been investing and collaborating with different partners in pilot projects and laboratories to find solutions for all six layers. Not only to find more sustainable alternatives but also with recyclability in mind. We will only replace a component if and when we find an equally effective solution.

Replacing MDI with bio-circular materials

The share of MDI's total carbon footprint is 51% (cradle-to-gate A1-A3), MDI is a chemical derived from fossil fuels. We’ve looked into ways to partially replace this MDI content with renewable bio-based feedstock. And with success!

With Eurowall Impact and Eurothane Silver Impact we have developed an entire product line with 25 % bio-circular content, cutting our carbon footprint by 43%*

Replacing polyols with lignin

We’ve been actively participating in a flagship project to partially replace the fossil-based polyols in our PIR insulation boards with high-quality lignin from sustainable hardwood. The result?

Read more

Switching to PEFC-certified paper for multilayer facings

As the first PIR/PUR manufacturer in the world, we are switching to PEFC certified paper for the multilayer facings of our PIR insulation boards. 16 out of 41 products are already certified.

Read moreRecticel Impact

Our first insulation line made with bio-circular materials is a fact. We’ve replaced 25% of the fossil-fuel based materials in Eurowall® Impact and Eurothane® Silver Impact with bio-circular alternatives, cutting their carbon footprint by 43%*.

*Internal LCA calculation based on EN15804+A2 standard, for modules A1-A3 (cradle to gate), based on mass balance approach